Technical Consultation, Product Solutions, And Maintenance Services

——Exploration, Research And Development, Exquisite Craftsmanship——

Technical Consultation

The adoption of new technologies and the development of new products, especially high-tech products, may generate certain risks, which may cause losses to existing investment costs and determine the complexity of business and system functions in the new operating environment. Through technical expert consultation, we will assist clients in conducting detailed discussions and evaluations of the characteristics and specific business needs of new technologies, reducing the risks associated with developing new technologies and products.

Technical consulting services are conducted through the signing of a technical consulting contract, where the party requesting and paying for the contract subject matter is the principal, and the party providing specific technical project results is the commissioned party, i.e. the consultant. The subject matter of a technical consulting contract is extensive, including soft science research projects and professional technical projects related to science, technology, economy, and social development. During the performance of the technical consulting contract, the client shall provide technical information and working conditions to the consultant; The consulting party, with its specialized knowledge, information, skills, and experience, applies scientific methods and advanced means to conduct research and investigation, and writes a technical consulting contract, proposing suggestions and the best or several alternative solutions for the client to refer to when making decisions. Usually, the consulting firms providing technical advice are research institutions and colleges, while the commissioning parties are usually relevant national agencies, functional departments, and production enterprises.

Product Proposal

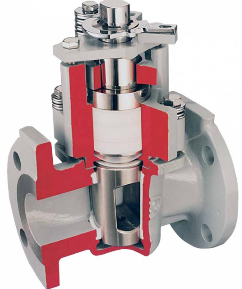

BNN has always been committed to relying on technological progress and continuous independent innovation. It actively cooperates with universities and research institutes to develop high-quality products using new technologies, processes, and materials. Especially in the materials of high-pressure wear-resistant valves, low-temperature and high-temperature engineering materials, special alloys, etc., it has conducted extensive research and application, making similar products reach international standards. Our main products include high-temperature and high-pressure wear-resistant metal sealed ball valves, metal sealed butterfly valves, high-pressure Y-shaped globe valves, bidirectional triple seal plug valves, eccentric disc plug valves, bidirectional rotating hemispherical valves, etc. The product specifications are DN15~DN2200, nominal pressure PN0.1~PN760, working temperature -196 ° C~700 ° C. The valve materials include carbon steel, alloy steel, stainless steel, Hastelloy alloy, nickel alloy, titanium alloy, zirconium material, etc. The driving modes include manual, electric, pneumatic, gas-liquid linkage, etc.

The product business scope covers: PetroChina, Sinopec, CNOOC, power plants, nuclear power, metallurgy, pharmaceuticals, environmental protection, military and other fields. Involving non-standard product technology transformation, technical exchange, maintenance and repair, domestic substitution, etc.

Repair Service

BNN has partnered with valve maintenance service partners from multiple locations to form a team of skilled engineers in operation and maintenance. We understand that providing international standard services not only requires quick response, but also better and more suitable solutions. National Rapid Response Service Centers: Shenyang, Zibo, Tianjin, Wuhan, Urumqi, etc. In order to further enhance our competitiveness, we fully utilize our regional advantages and combine "manufacturing" with "service" to quickly respond to customer needs with a "service" attitude. Our technical personnel have accumulated a wealth of control valve manufacturing and maintenance skills through long-term work experience. Using the manufacturing service system, sort out the technical standards and operating specifications for control valve point inspection, maintenance, and upkeep, and form a standardized plan for control valve point inspection and repair. Committed to serving every customer well. By fully communicating with users, understanding their needs, and tailoring maintenance plans for them.

BNN provides fast, convenient, and efficient maintenance, repair, and upkeep services for various control valves for enterprises in industries such as petroleum, chemical, metallurgical, pharmaceutical, fertilizer, electricity, and nuclear power; At the same time, provide various spare parts and vulnerable parts according to user needs. And we promise to provide a 12-month warranty for maintenance services and optional products and accessories.

Standard process: Communicate project content with customers - pre preparation - maintenance project planning - maintenance project execution - preparation of handover materials. The company's standardized maintenance process includes five steps, providing customers with professional and efficient high-speed maintenance and safety guarantees.

—— COMPANY PROFILE ——

Shanghai Bnn Valve Technology Co., Ltd. is a modern technology and research and development enterprise that integrates research and development, production, sales, and service. The company fully utilizes its personnel and technological advantages and has established good strategic partnerships with multiple companies in the valve industry. With technological innovation as the core and customer market orientation, it adheres to the concept of quality first and focuses on the research and development, production, and technological transformation of high-quality and high-end valves. In response to the national policy of "substituting the country for progress", we aim to address valve issues related to the renovation, replacement, maintenance, and repair of imported valves in various industries. Committed to creating more professional, high-quality, safe, technological, and advanced valve products and technical services in the global valve field.

+ Years Of Industry Experience

+ Home Service Customers

+ Intellectual Property Rights

New Product

—— New Technologies And Processes ——